Lots of people use blood collection tubes every day, but they don’t think about them until they need them. These little tubes are very helpful in hospital, clinic, and testing labs. They help keep blood safe while it is being collected, stored, and transported so that it can be tested correctly. Every blood collection tubes manufacturers that makes them that has to follow strict rules for quality, cleanliness, and safety. If you choose the wrong provider, you could end up with a contaminated sample, wrong test results, or even risks to patient safety.

This guide aims to how to choose the right blood collection tubes manufacturer, explain the various tube types, and give you advice to get the best deal and quality for your needs.

Why Blood Collection Tubes Matter in Healthcare

Blood collection tubes are more than just containers. They have a direct role in test accuracy and patient care. If the wrong additive is used, or if the tube isn’t sterile, test results can be wrong. That could lead to the wrong diagnosis or delayed treatment.

The Role of Blood Collection Tubes Manufacturers

Reliable manufacturers are responsible for:

- Designing tubes with exact chemical additives like EDTA, citrate, or heparin

- Keeping production facilities sterile

- Meeting ISO, CE, and FDA compliance and certification standards

- Labeling tubes with clear color codes and expiry dates

A trustworthy manufacturer understands that they aren’t just making a product — they’re making something that could impact a patient’s life.

Types of Blood Collection Tubes and Their Uses

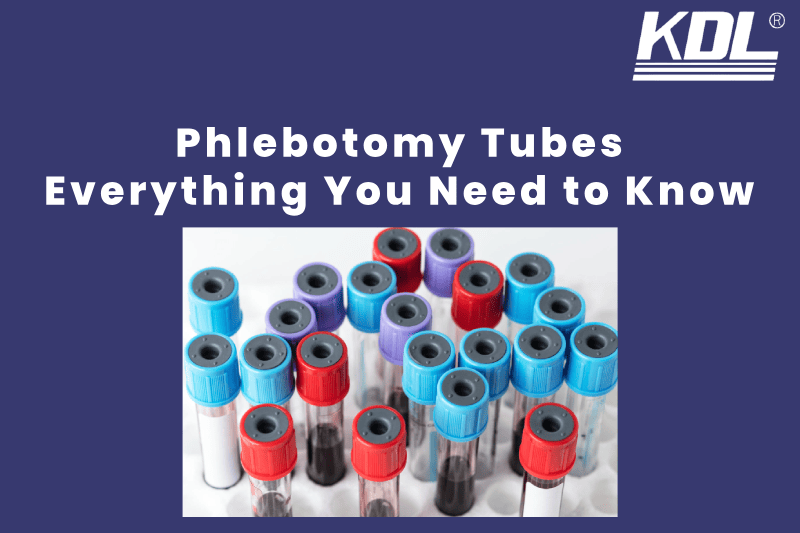

Different blood tests require different types of tubes. Here are the most common types made by top blood collection tubes suppliers.

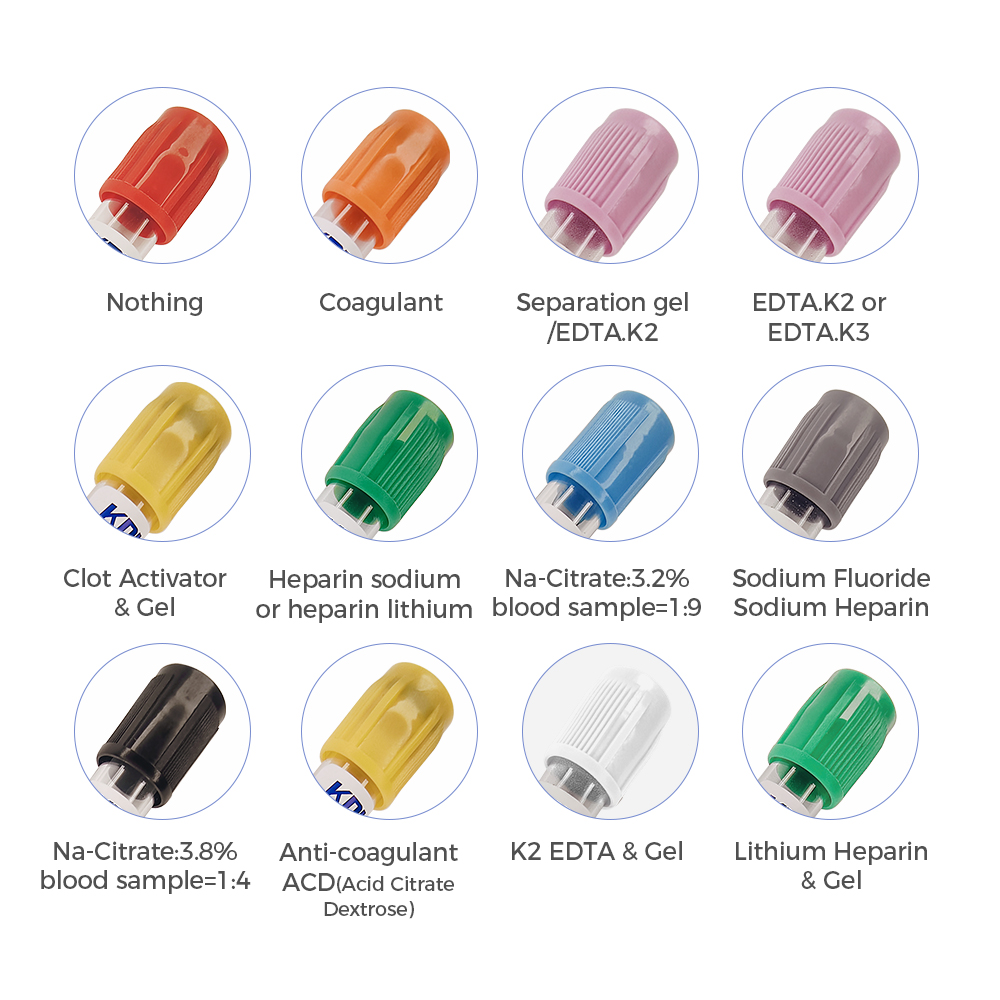

Common Tube Types

- EDTA Tubes – Best for hematology tests like complete blood counts (CBC). EDTA stops blood from clotting.

- Citrate Tubes – Used for coagulation studies to measure blood clotting time.

- Heparin Tubes – Used for plasma chemistry tests; prevents clotting with minimal interference.

- Serum Tubes – No anticoagulant; used for many chemistry and immunology tests.

- Vacuum Tubes – Pre-sealed to reduce contamination risk and make collection easier.

💡 Many specimen sollection products manufacturer and supplier offer discounts for hospitals and labs that buy in bulk.

What to Look for in a Blood Collection Tubes Manufacturer

1. Certifications and Compliance

Make sure that any provider you choose meets the severe rules set by the industry before you hire them. A blood collection tube manufacturer that is ISO certified has shown that they maintain high standards while making medical devices. If you want to sell in Europe, you need to get CE Marking, which shows that the tubes exceed EU safety and performance standards. FDA clearance is very important for the U.S. market since it shows that the product is safe, works, and meets all federal rules.

2. Product Quality and Testing

You need a manufacturer that takes product testing carefully since the quality of blood collection tubes has a direct impact on patient safety and test accuracy. Find suppliers that do sterility tests to make sure there is no contamination, additive accuracy checks to make sure each tube has the proper chemical makeup, and leak-proof tests for vacuum-sealed tubes to keep samples from being lost. Getting a quality control report or sample batch results might help you trust that the manufacturer’s promises are true.

3. Production Capacity and Lead Times

A excellent manufacturer is only useful if they can meet your needs on schedule and in the right amounts. Find out how much they can make in a month to evaluate whether they can manage your order quantity, particularly when demand is strong. Trusted manufacturers typically provide emergency supply choices for medical demands that need to be met right away. Also, ask them how long it usually takes to fill regular and special orders. This can help you manage your inventory and prevent running out of supplies that might affect patient care.

4. Customization Options

Working with a bespoke blood collection tubes maker might help your items stand out if you’re developing a brand or have particular needs. A lot of suppliers can print your logo right on the tube, make custom packaging that fits with your brand, or change the color coding on the caps so that tests are easier to find in the lab. Customization may help your goods stand out, make your workflow more efficient, and boost your market presence. But this is only true if the manufacturer has the proper skills and expertise in OEM manufacturing.

Factors to Consider When Selecting OEM Manufacturers for Customized Blood Collection Tubes

Choosing the right OEM blood collection tubes manufacturer is critical if you want to create a reliable, branded, and regulatory-compliant product. Here’s what you should evaluate before signing a long-term contract:

1. Certifications and following the rules

Only work with ISO certified OEM blood collection tube manufacturers.This approval makes sure that they follow strict rules for managing quality for medical devices. You have to get CE Marking on your tubes if you want to sell them in Europe. This shows that they meet EU safety and performance standards. Keep in mind that the OEM must be FDA-registered and follow all rules for the U.S. market. If you don’t have these qualifications, your goods might be held up in customs, fined, or even banned in some places.

2. Relevant Industry Experience

Custom vacuum blood collection tubes aren’t something that all OEM manufacturers are good at making. Find companies that have done similar work for other medical signifies and done it well. Experienced makers know how important it is for accurate lab processing that additives are dosed correctly, caps are sealed tightly, and the colors of the caps are labeled. So, mistakes in making won’t happen as often and cost as much.

3. Customization Capabilities

A good OEM partner should give you a lot of ways to customize your product, like

- Putting your name or logo right on tubes

- Making private label boxes

- Using certain materials, like medical-grade glass or PET

- Changing the colors of caps to fit the needs of your lab’s workflow

- Changing the mix of additives for specific tests

In a market with a lot of competition, these features help you stand out while still meeting your testing needs.

4. Minimum Order Quantity (MOQ) and Production Capacity

For OEM making to be cost-effective, there is usually a minimum order number. Find out from your source what the minimum order quantity (MOQ) is for handmade tubes and if they can increase their production if your need increases. A good OEM maker will also have backup plans for when they need to quickly fill large orders of blood collection tubes without lowering the quality.

5. Quality Control and Testing Protocols

At every stage of production, your OEM partner should keep strict quality control standards. Among these are:

- Testing for sterility to avoid the risk of infection

- Verification of additive measurements for correct lab reports

- Testing for vacuum leaks to make sure tubes stay intact while they are being stored and shipped

Before you sign a contract, ask to see their quality control paperwork or results from a third-party lab.

6. Tooling and Prototype Development

Before you start mass production of a new product design, ask the OEM if they can make unique models and samples. Before placing a big order, this step lets you test the product’s performance, branding, and usefulness.

7. Transparent Pricing and Payment Terms

When OEMs customize products, they often have to pay for tools, materials, and production costs per unit. Ask for a full list of all costs and make it clear if the tools fees are one-time or ongoing. Also, look over the payment terms. Some sellers may need deposits up front, while others offer payment choices based on milestones or after delivery.

8. Communication and Project Management

Clear communication is key to having strong OEM relationships. Your maker should give you a personal account manager who will be in charge of changes, technical questions, and fixing problems. Misunderstandings about design specs, delivery plans, or legal compliance are less likely to happen when people talk to each other regularly.

Tip: Before agreeing to a large-scale OEM production run, you should always place a test order. This lets you check the quality of the products, the accuracy of the packing, and the dependability of the delivery without spending a lot of money.

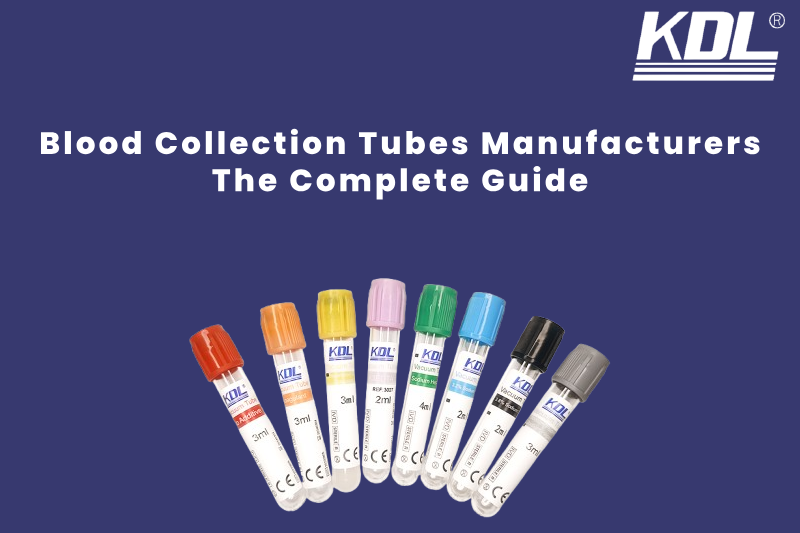

KDL – Trusted OEM Blood Collection Tubes Manufacturer and Supplier

KDL is a reliable OEM blood collection tube manufacturer and supplier that provides premium vacuum blood collection tubes that are certified by ISO , follow FDA guidelines, and have exact additive formulas. We helps hospitals, labs, and wholesalers around the world with dependable production capacity, quick lead times, and strict quality control for accurate, safe, and legal blood collection solutions.

Conclusion

Whether you’re purchasing from a standard blood collection tubes manufacturer or working with an OEM supplier for customized vacuum tubes, the supplier’s quality, compliance, and delivery reliability will directly affect your operations.

By following this guide, you can secure a supplier that provides safe, sterile, and compliant blood collection tubes — at the right price, in the right quantity, and on time.

Blood Collection Tubes FAQ

1. What are the different types of blood collection tubes?

Blood collection tubes come in various colors, each indicating a specific additive and purpose. Common types include:

- Red Top: No additive (for serum tests).

- Lavender (Purple) Top: EDTA (for hematology tests like CBC).

- Green Top: Heparin (for plasma chemistry).

- Blue Top: Citrate (for coagulation tests like PT/INR).

- Gray Top: Fluoride/oxalate (for glucose testing).

2. How to choose the right blood collection tube for my test?

The tube color depends on your lab test requirements:

- Serum tests (e.g., cholesterol): Red or gold (gel separator).

- Complete blood count (CBC): Lavender top.

- Coagulation tests: Blue top.

Always consult your lab’s guidelines to avoid errors.

3. What happens if I use the wrong blood collection tube?

Incorrect tubes may lead to:

- Clotting errors (e.g., using red instead of blue for PT/INR).

- False results (e.g., EDTA altering calcium levels).

- Sample rejection by labs. Always verify tube compatibility before collection.

4. Where to buy sterile blood collection tubes in bulk?

We supply FDA/CE-certified blood collection tubes for hospitals, clinics, and labs. Bulk orders available with discounts. Contact us for a quote!

5. Why do some blood collection tubes contain gel?

Gel separator tubes (e.g., gold or red-gray tops) contain a thixotropic gel that separates serum/plasma from cells during centrifugation, improving testing efficiency.

6. Why was my blood sample rejected by the lab?

Common reasons include:

- Underfilled or overfilled tubes.

- Incorrect mixing (e.g., not inverting blue top 3-4 times).

- Using expired tubes. Check our blood collection guide to avoid errors.

7. Glass vs. plastic blood collection tubes: Which is better?

- Glass tubes: More stable for certain tests but fragile.

- Plastic tubes: Shatterproof and ideal for shipping. Most modern labs use plastic.

8. Are your blood collection tubes FDA/CE/ISO certified?

We provide volume-based pricing for orders above 100,000 units, with flexible logistics (sterile packaging, express shipping). Request a quote for tiered discounts.

9. Can you customize tube labels or additives for research studies?

Yes! We offer:

- Barcoded labels (2D/linear).

- Custom anticoagulant volumes (e.g., low-volume pediatric tubes).

- OEM branding. Contact our R&D team for specs.

10. How do you ensure batch consistency in tube manufacturing?

We adhere to ISO 13485 with:

- Lot-specific COA (Certificate of Analysis).

- QC checks for vacuum pressure, clot activation, and hemolysis rates.

11. Are your tubes compatible with BD Vacutainer holders/needles?

Yes, our tubes use standard Luer-lock interfaces, compatible with major brands’ equipment.

12. Do you offer sharps waste-friendly tubes for high-throughput labs?

Our safety-engineered tubes reduce needlestick risks with:

- Retractable needles.

- Recyclable plastic materials (PET).

+86-791-8686-1216

+86-791-8686-1216